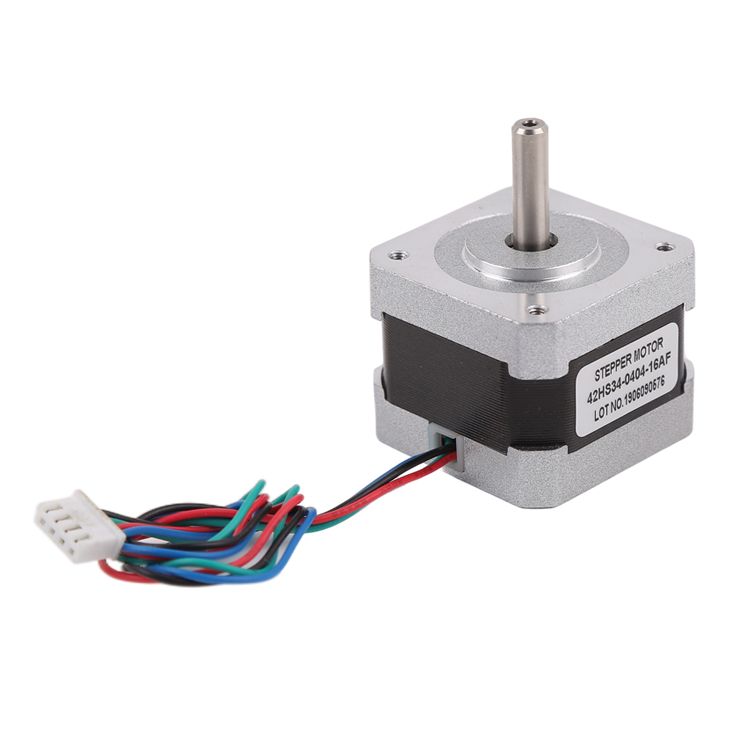

42-міліметрові гібридні крокові двигуни в 3D-принтерахє поширеним типом двигуна, який використовується для руху друкуючої головки або платформи 3D-принтера. Цей тип двигуна поєднує в собі характеристикикроковий двигун і коробка передачз високим крутним моментом і точним кроковим керуванням, що робить його широко використовуваним у сфері 3D-друку.

I. Принцип дії

Принцип роботи42-мм гібридний кроковий двигунбазується на поєднанні крокового двигуна та редуктора. Кроковий двигун – це пристрій, який перетворює електричні імпульси на обертальний рух, тоді як редуктор перетворює обертальний рух двигуна на потрібну швидкість та крутний момент.

У 3D-принтерах, a42-міліметровий гібридний кроковий двигунзазвичай підключений до екструдера друкуючої головки. Коли система керування принтером надсилає електричний імпульс до двигуна, двигун починає обертатися. Обертальний рух двигуна перетворюється на лінійний рух екструдера за допомогою шестерень у редукторі. Цей лінійний рух приводить екструдер вперед або назад для екструдування пластикової нитки на друкуючу головку.

II. Переваги

Високий крутний момент: 42-міліметровий гібридний кроковий двигун має високий крутний момент, що забезпечує достатню силу для приведення екструдера на друкувальну головку. Це дозволяє двигуну долати тертя та інший опір пластикового філаменту під час процесу друку, забезпечуючи стабільність друку.

Точне керування: 42-міліметровий гібридний кроковий двигун забезпечує точне керування екструзією завдяки можливості точного керування кроковим двигуном. Система керування принтером може надсилати електричні імпульси для керування кількістю кроків обертання двигуна для досягнення точної відстані екструзії. Така точність керування важлива для забезпечення якості друку та запобігання втратам матеріалу.

Гарна стабільність: Гібридні крокові двигуни зазвичай мають низький рівень шуму та вібрації, тому забезпечують гарну стабільність. Це допомагає гарантувати відсутність небажаних перешкод або проблем, що впливають на якість друку під час процесу друку.

Легка інтеграція: 42-міліметрові гібридні крокові двигуни мають менший розмір та легку інтеграцію, що дозволяє легко інтегрувати їх у різноманітні 3D-принтери. Ця особливість робить гібридні крокові двигуни ідеальними для багатьох малих та домашніх 3D-принтерів.

III. Сценарії застосування

Друк на пластику:42-міліметрові гібридні крокові двигуни широко використовуються в галузі 3D-друку пластиком.У процесі друку на пластику двигун приводить в дію екструдер для екструдування пластикового філаменту на друкувальну головку, реалізуючи пошарове створення пластикових об'єктів. Крутний момент та точне керування двигуном дуже важливі для забезпечення якості та ефективності друку.

Друк металу: 42-міліметрові гібридні крокові двигуни також часто використовуються в процесі 3D-друку металу. Хоча друк металу вимагає вищих температур і тиску, гібридні крокові двигуни все ще забезпечують достатній крутний момент і точне керування для задоволення потреб. Друк металу вимагає від двигунів більшої стабільності та стійкості до високих температур.

Друк біоматеріалів: Друк біоматеріалів вимагає використання спеціальних біосумісних матеріалів, таких як клітини, фактори росту тощо. 42-міліметрові гібридні крокові двигуни можуть використовуватися для керування екструдерами біоматеріалів для точної екструзії та контролю біоматеріалів. У цьому випадку гігієна та надійність двигуна дуже важливі для забезпечення якості та безпеки друку.

IV. Міркування

Адаптивність: Вибираючи 42-міліметровий гібридний кроковий двигун, вам потрібно адаптувати його до моделі та специфікацій вашого 3D-принтера. Різні моделі та специфікації двигунів можуть більше підходити для конкретних принтерів, тому вибір правильної моделі та специфікацій двигуна є критично важливим для забезпечення якості та ефективності друку.

Технічне обслуговування: Оскільки гібридні крокові двигуни піддаються тертю та нагріванню під час безперервної роботи, вони потребують регулярного технічного обслуговування. Це включає заміну мастильних матеріалів, очищення двигуна та коробки передач, а також перевірку проводів і з'єднань. Регулярне технічне обслуговування подовжує термін служби двигуна та підвищує ефективність друку.

Надійність: Вибираючи 42-мм гібридний кроковий двигун, необхідно враховувати надійність.

Час публікації: 05 грудня 2023 р.